- AquaCycle

- Proteins4Singapore

- Singapore's Pathway to Carbon Neutrality

- CellFACE

- LightSPAN

- Computational Modelling Group

- Energy and Power Systems Group

- SITEM - Singapore Integrated Transport and Energy Model

- MoVES (Mobility in Vehicular Environments at Scale) lab

- Projects

The Field Trial of Precast Ultra-Thin Whitetopping (PUTW)

Almost all the roads in Singapore are paved with an asphalt pavement. A rigid (concreate) pavement is used at junctions and bus stops to prevent rutting. However, extended road closure during the rigid pavement maintenance and rehabilitation process can lead to a very high user delay cost at heavy traffic corridors because of the concrete setting time. This user delay cost is estimated at a value of 1000 SGD/m2 according to a study done by Nen NguyenDinh et al. (2016) at one study area in Singapore. To reduce this significant user delay cost, TUMCREATE has developed an innovative pavement concept called Precast Ultra-Thin Whitetopping (PUTW) that can be constructed quickly overnight. PUTW can help to reduce the road closure from 10 days using conventional concrete pavement to 8 hours.

In collaboration with Nanyang Technological University, TUMCREATE is conducting a field trial project of PUTW in Singapore. This project is funded by Jurong Town Corporation (JTC), a Singapore state owned company. It is a 3-year project including installation, testing and monitoring.

The PUTW Field Trial Concept

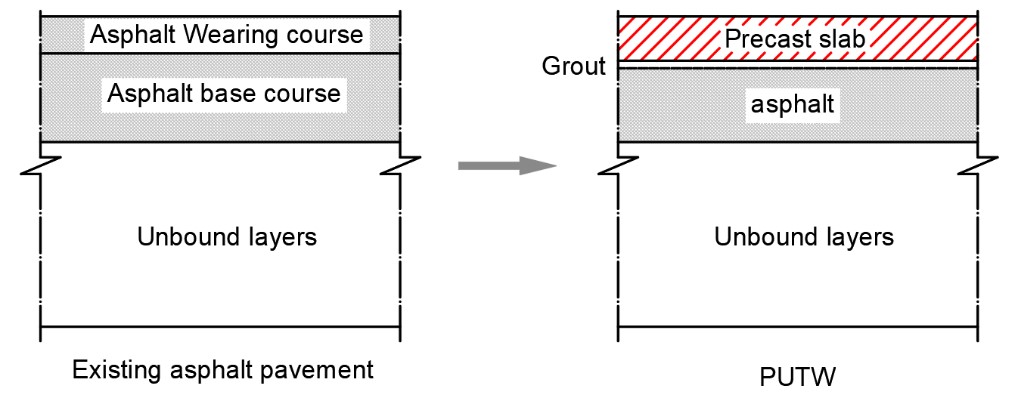

The field trial of PUTW was executed at a bus stop along Tembusu Crescent in Jurong Island, Singapore. The top layer of the asphalt pavement at the bus stop was milled off and replaced with thin precast concrete slabs. The precast slabs were placed and levelled using special lifting / levelling devices. After that, fast setting grout was used to fill the small gaps between the precast slabs and the asphalt. Figure 1 depicts the PUTW pavement concept and the slab arrangement at the bus stop is shown in Figure 2.

Figure 1: The pavement concept

Figure 2: Slab arrangement

The precast concrete slabs can be as thin as 7cm, but they must be durable enough to withstand the construction load (slabs lifting with all impact factors). Therefore, Engineered Cementitious Composite (ECC) was chosen. ECC is a unique type of high-performance fibre-reinforced cementitious composite. ECC has a very high ductility, which translates into a high flexural strength. In collaboration with NTU, a new version of ECC was developed using locally available raw materials in Singapore

ECC is a cementitious material without any coarse aggregate, therefore the pavement surface doesn’t provide good road grip. A method of introducing corundum, a very hard and durable material, to the ECC mixture has demonstrated to provide sufficient grip for vehicles (Bawono, et al., 2017) (NguyenDinh, et al., 2018).

The pavement test section at the bus stop is instrumented with strain gauges, displacement and temperature sensors for monitoring the performance of PUTW over time.

Team

Dr. Nen NguyenDinh

PUTW Developer, Project Leader

Dr. Bernhard Lechner

Scientific adviser

M.Sc. Ali Bowano

Project engineer

Dr. Andreas Rau

Principal Investigator

Asst. Prof. En-Hua Yang

NTU Principal Investigator

Dr. Jishen Qiu

NTU Collaborator

Kian Wee

JTC Co-Principal Investigator

Contact: Dr.-Ing. Nen NguyenDinh (nen.nguyendinh@tum-create.edu.sg)